LONG BEACH, Calif. — President Donald Trump’s Department of War is betting big on a “new-guard” of weapons manufacturers in his push to expand domestic defense production.

After decades of legacy suppliers dominating Pentagon contracts, Secretary of War Pete Hegseth is declaring the market “wide open” for upstart weapons manufacturers. The Daily Caller News Foundation traveled with the secretary to two upstart California weapons companies earlier in January as a part of a multi-state examination dubbed the “Arsenal of Freedom” tour.

“The days of rewarding the comfortable old guard for failure are finished,” Hegseth told aerospace company Rocket Lab in Long Beach, California. “Washington plays games with lobbyists and accountants and bureaucrats. It plays games to block out new contestants, new competitors. That’s the whole point — a circular process that enriches and benefits the same people.”

“We will provide larger, longer, and more predictable contracts to companies like this one,” Hegseth said at Rocket Lab. “The field is wide open.”

Secretary of War Pete Hegseth delivers remarks at Divergent on Jan. 8, 2026. (Photo by The Daily Caller News Foundation)

“The idea with these new entrants is they don’t have a legacy technology stack to build on — they’re starting from scratch,” a senior War Department official told reporters during Hegseth’s California tour. “They’re using new manufacturing techniques at the start, and therefore, ideally, they could produce mass quantities cheaper.”

Both of the fledgling manufacturers Hegseth toured notably adhere to a zero Chinese-reliance policy in their supply chains, a sharp departure from their legacy counterparts. The second largest U.S. military contractor in 2022, RTX (formerly Raytheon) relies on Chinese suppliers for “95% of the commodities related to aircraft and spacecraft parts … 100% of tubes, pipes, hoses, and fittings … [and] 54% of Raytheon’s electric motors and generators,” according to a 2023 TenderAlpha analysis.

“We’re trying to adopt the same model, where they invest their capital first — the venture capitalist, they take the risk, not the American taxpayer. And when they deliver, we buy it,” the official continued. “This is a big revolution for the Department of War. We’ve never had that kind of business model, if you will. And if we get that, we can have increased competition and we’re not subject to just five clients.”

A graphic at Castelion in Long Beach, California (Photo by The Daily Caller News Foundation)

Missiles From ‘Scratch’

“We started the company in 2022. Castelion is barely 3 years old,” Castelion co‑founder and CFO Andrew Kreitz told reporters during Hegseth’s tour of the company headquarters in Long Beach, California. “The reason we exist is to change the way the United States develops and manufactures hypersonic missiles.”

Hypersonics – missiles that fly faster than five times the speed of sound – are seen as a key tool of modern warfare. Kreitz warned that Americans would be “shocked” to learn just how far behind U.S. industry is.

“Our adversaries, particularly the Chinese, are without exaggeration two decades ahead of us in [hypersonic] technology… and far ahead in manufacturability and production rate,” he said.

Castelion boasts a supply chain operating “entirely independent of China,” and hires only American citizens.

“It’s strategically critical, right? The whole point is that we’re able to build things here,” Kreitz said. “You need to get to hardware early, you need to test, then you need to iterate fast, and then do it again. The way that you’re able to do that is, anywhere that you need to, vertically integrate. So we’re not afraid to do manufacturing in-house.”

The company announced in December that it had raised $350 million in funding — a “game-changing” infusion Kreitz said will let them finish and fly their first weapon, a missile called Blackbeard.

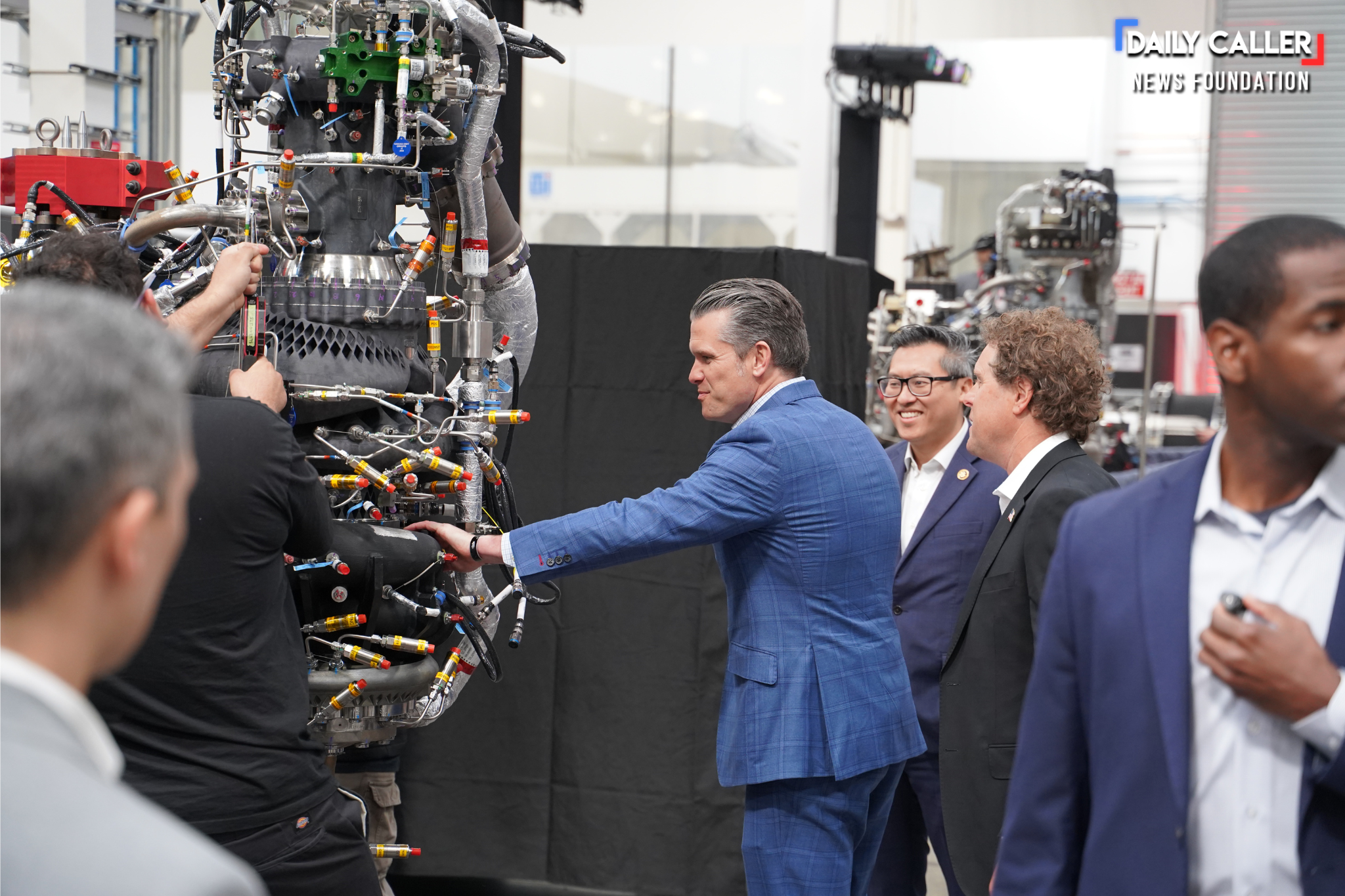

Hegseth tours Rocket Lab in Long Beach, California (Photo by The Daily Caller News Foundation)

“These companies haven’t yet developed huge production lines like Lockheed … they’ve got great technology, and now we’re trying to get them their first production line,” said a senior War Department official. “What’s unique about Castelion, they make a hypersonic missile … the Chinese have those kinds of things, we have them too, but they’re very expensive. We pay $50-60 million per—they’re trying to do the same thing for $300,000-400,000.”

Kreitz also noted that he and his fellow co-founders are all veterans of Elon Musk’s SpaceX – and many of their engineers come from Silicon Valley culture.

“All three of the co-founders are ex-SpaceX, a lot of folks out on the floor, the engineers or technicians, a lot of them are ex-SpaceX,” Kreitz said. “Having a culture that is risk-on, that is aggressive, that is willing to get to hardware as early as possible, test as early as possible, iterate as fast as possible — that is the team.”

A warning sign at Rocket Lab (Photo by The Daily Caller News Foundation)

3D Printing The Arsenal

Hegseth also toured Divergent Technologies, a firm founded in 2016 that cut its teeth in automotive manufacturing before pivoting to defense. Divergent employs cutting edge 3D printing processes using powder bed fusion — sometimes called “additive manufacturing” — that they say yield a huge time-to-market advantage on complex parts.

“Divergent is a company that is pioneering additive manufacturing … they can basically 3D print missile bodies and structures,” the War Department official said of the company. “This holds tremendous promise to support things like the Patriot [missile] deal, where we’re trying to triple production in the defense industrial base, and scale it up with these additive manufacturing machines that give us the ability to build with fewer humans in the loop, using modern technology and digital engineering.”

“In plastic 3D printing, you’re adding new bits of hard material to the print bed, layer by layer by layer,” a senior Divergent official told reporters during the tour. “In laser powder bed fusion, you have an ocean of powder that’s loose, and you are melting the specific pieces of the ocean that you want to turn into a shape.”

Additive manufacturing has been in use in aerospace applications since the 1990’s, but has recently become effective due to advancements in robotics assembly, the Divergent official said.

“The reason we are able to make it work on our systems is because, as you said, we’ve combined it with AI driven design and robotic assembly at the end of the line,” the Divergent official said. “If you’re just making small piece parts with additives, it doesn’t matter how advanced your machine is, in my view, it’s not a good enough reason to use additive. You need some system level, functional integration.”

Rocket Lab in Long Beach, California (Photo by The Daily Caller News Foundation)

“We can get to actual hardware faster, and at faster speeds, too,” the Divergent official said. “We can actually scale it faster than you can with conventional cast technologies because we have way fewer parts to deal with here.”

Like Castelion, Divergent also touts a zero reliance on Chinese suppliers, a deliberate policy aimed at “independence from Chinese supply chains,” the Divergent official said.

“We recognize the importance of independence from Chinese supply chains as just a core focus in the national security environment that we’re currently in,” the Divergent official said. “So today we have zero Chinese supply chain reliance.”

Divergent believes its approach could help increase production of systems like the Patriot missile by printing bodies in fewer steps and keeping “fewer humans in the loop” — a metric it calls “touch-labor.”

“This is why every major contractor works with us, right?” the Divergent official said. “We are kind of their silver bullet to solving all of these structural supply chain issues, with castings, with forging.”

Divergent also draws talent from Musk’s SpaceX. One Divergent engineer who formerly ran the Dragon spacecraft production team at SpaceX said that he took a lot of the learning from the company and brought it to Divergent to “increase their iteration rate … leveraging this kind of iterative, fast paced design approach that I brought over from my time at SpaceX.”

Trump on Jan. 7 called for a hefty new 2027 military budget and penned an Executive Order articulating new requirements for defense contractors which the administration says are “single-mindedly [pursuing] investor profits at the expense of warfighter capability and readiness.” The push for an increased $1.5 trillion 2027 budget — expanding current military spending set at $901 billion — comes only weeks after the Pentagon failed its annual audit for the eighth consecutive time.

Content created by The Daily Caller News Foundation is available without charge to any eligible news publisher that can provide a large audience. For licensing opportunities of our original content, please contact licensing@dailycallernewsfoundation.org